Transforming E-Waste Into Riches: The Story of a UK Coin Producer

Transforming E-Waste Into Riches: The Story of a UK Coin Producer

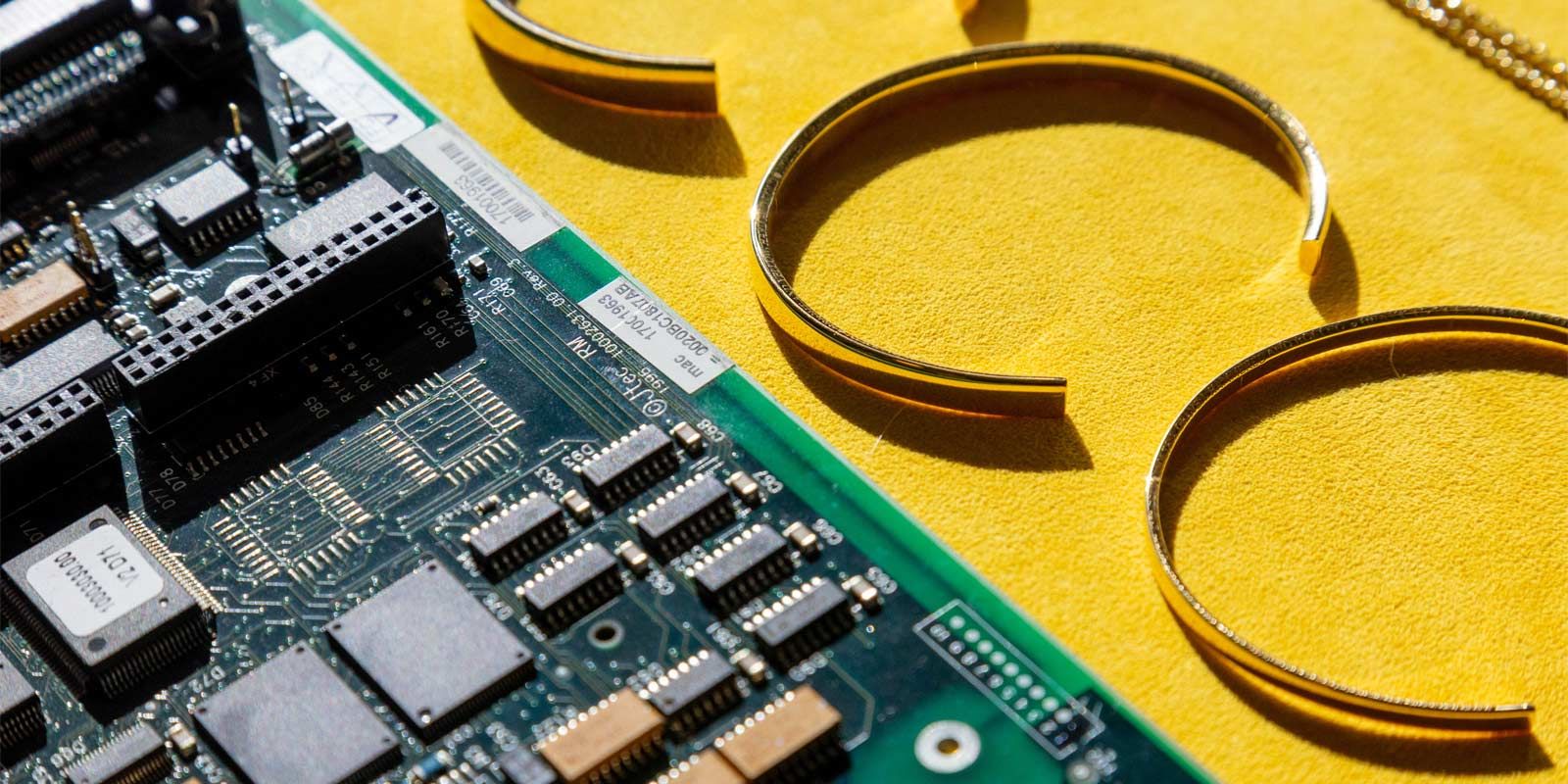

The Royal Mint, the United Kingdom’s official coin maker, has opened a “pioneering new factory” that extracts precious metal from everyday items and turns it into valuable jewelry.

Based in South Wales, the new facility, which began construction in early-2022, will enable the coin-making company to turn up to 4,000 tonnes of circuit boards from UK-sourced discarded devices into high-end rings, earrings, and necklaces for its 886 jewelry range.

The Royal Mint is using cutting-edge technology pioneered by Excir, a Canadian clean tech firm that prides itself on sustainability. The innovative machinery recovers 99% of precious metals from e-waste in a way that has minimal adverse impact on the environment. After separating the circuit boards’ metals from their other components in a specialized plant, the parts containing gold will be sent to Llantrisant, South Wales, where a spinning drum will clean the materials, and an acidic mix will dissolve the gold in as little as four minutes, ready for manipulation into sellable items. Meanwhile, the residual constituents will be treated for onward processing for use in other areas.

The Royal Mint

This radical method of extracting gold enables the coin manufacturer to reduce its dependence on traditional mining methods. Indeed, the rapid process operates at room temperature, meaning a significantly cleaner, more efficient, and more cost-effective gold-recovery operation. As a result, Excir’s chemistry helps to tackle the worldwide issue of increased e-waste generation , which is rising by 2.6 million tonnes every year, according to the United Nations’ Global E-waste Monitor. Excir says it is committed to reaching a zero-landfill impact through its artisanal technology.

Given the rise in cashless transactions, thanks to online banking and contactless card payments, The Royal Mint has had to diversify to protect not only its workforce, but also its long-term survival. Chief Executive Anne Jessopp says, “The Royal Mint is transforming for the future, and the opening of our Precious Metals Recovery factory marks a pivotal step in our journey. We are not only preserving finite precious metals for future generations, but we are also preserving the expert craftmanship The Royal Mint is famous for by creating new jobs and reskilling opportunities for our employees.”

The Royal Mint, which is owned by the UK Treasury, has hinted that it also plans to use some of the extracted gold in other streams of its operations in the future. For example, the company produces collectible commemorative coins and gold bars made from 999.9 fine gold, and this new tech opens new avenues for collectors to get their hands on some truly 21st-century products.

Source: Excir , The Royal Mint , The Guardian

Also read:

- [New] In 2024, Cutting Edge Techniques for Clear Zoom Captures

- [New] Share Across Platforms Instagram Meets Facebook

- [New] Step-by-Step Process to Enhance OBS with Effective LUT Filters

- [New] Top 12 Capture Providers, Never Stop

- Expert Insights on Gadgets by Tom's Hardware HQ

- Get the Latest Canon MG3600 Drivers for Smooth Printing Experience - Download Here!

- In 2024, How To Remove or Bypass Knox Enrollment Service On Xiaomi 14 Pro

- In 2024, How To Simulate GPS Movement With Location Spoofer On Poco F5 Pro 5G? | Dr.fone

- Next-Gen Processor Breakthrough: Discover Ampere's AmpereOne Aurora, Featuring an Impressive 512 Cores and Customized AI Engine Supporting HBM Memory Technology

- Pattern Locks Are Unsafe Secure Your Realme GT 3 Phone Now with These Tips

- The Price Reveal Is Here! Get Your Hands on Asus' New Computing Marvels - NUC 14 Pro at $394, NUC 14 Pro+ for $869

- Ultimate Guide to Installing Logitech G29 Race Wheel on Windows Operating Systems: Win 7/8/10

- Unlock the Mystery: Understanding 'Beyond The Wire' And Its Aftermath

- Updated FCPX Mastery Learn the Top 40 Keyboard Shortcuts

- Upgrading Intel or AMD CPU Drivers - Methods and Best Practices for Windows Users

- Title: Transforming E-Waste Into Riches: The Story of a UK Coin Producer

- Author: Joseph

- Created at : 2024-10-11 22:10:24

- Updated at : 2024-10-18 17:39:42

- Link: https://hardware-help.techidaily.com/transforming-e-waste-into-riches-the-story-of-a-uk-coin-producer/

- License: This work is licensed under CC BY-NC-SA 4.0.